Front Cover of Volume 14

Volume 14

by R Greenhalgh (Ed)

Published by Pitman & Sons Ltd

16th April 1927

No ISBN number

Extract from pages 652-654

Traversing a Mould

Great care is required when cutting the template, which must be perfectly true since any slight inaccuracy will be multiplied by the number of the voussoirs in the arch

To prove its accuracy, a process called traversing is adopted, see fig. 60a, 60b and 60c. Allowance is made

for the bed joints, whatever their thickness is to be

The finished template, being the exact size and shape

of each cut course of the arch

It is only necessary to set out a little more than half the arch, sufficient to include the key. Count the number of bed joints from the key to the springing line, and multiply this number by the desired thickness of the joint, which will give the total allowance for the joints in one-half of the arch

Mark this distance off from the springing point along the intrados, and draw a line parallel with the abutment

Get two light parallel straight-edges perfectly true, and place one along the radial line on the outside of the key

Now mark on the edge of the template a point coincident with the soffit line. Place the second straight-edge against this edge of the template, hold it firmly in position, and with a sliding motion draw both the template and the first straight-edge away; now place the first straight-edge against the edge of the one you are holding, and hold that firmly in position

Should it fall directly on this line, there will be no further need to repeat

If, in the first traverse, the template finishes beyond the line, then the soffit point will have to be moved down,

this slightly diminishes the width of the voussoirs

The Soffit Bevel

Square a line across the template from the pencil-point which marks the soffit line, reverse the square, place its stock against the other edge of the template, and draw a line from the same point.

In a camber arch, the soffit bevel for every course is different, and should be transferred from the setting-out drawing to the template when the traverse has been completed

Cutting the bricks

In axed work, a rough bench is required for scribing the bricks, and a cutting block for the axing. The actual method depends on the type of brick and the particular kind of arch

If the soffit bevel is very slight, it is best to cut, or rub, this bevel on the brick first. But if the bevel is acute, or if the bricks are glazed, the craftman will be compelled to leave the soffit untouched, and cut both sides of the brick to the wedge-shaped template

A good method in axed work is to tack a thin strip of wood across the template to the soffit line, and apply the mould with this strip abutting the end of the brick

Scribe the edges of the voussoir with a tin saw, which is usually a piece of tin plate let into the edge of a wood block and used like a mason’s grub saw

The saw is worked backwards and forwards, against the edge of the template, until a fine cut about ¼" deep is made in the face of the brick

The edges outside the cut are removed with the boaster, and the rough irregular surfaces trimmed with the scutch to form true beds

Each course of the arch is stacked as it is cut, until the whole arch has been completed. If the cutting has been accurately done, the work will stack close and the courses will not rock, or wobble, although they are unset

This is an excellent criterion of good workmanship

Work that is cut well will stack well

Great care is required when cutting the template, which must be perfectly true since any slight inaccuracy will be multiplied by the number of the voussoirs in the arch

To prove its accuracy, a process called traversing is adopted, see fig. 60a, 60b and 60c. Allowance is made

for the bed joints, whatever their thickness is to be

The finished template, being the exact size and shape

of each cut course of the arch

It is only necessary to set out a little more than half the arch, sufficient to include the key. Count the number of bed joints from the key to the springing line, and multiply this number by the desired thickness of the joint, which will give the total allowance for the joints in one-half of the arch

Mark this distance off from the springing point along the intrados, and draw a line parallel with the abutment

Get two light parallel straight-edges perfectly true, and place one along the radial line on the outside of the key

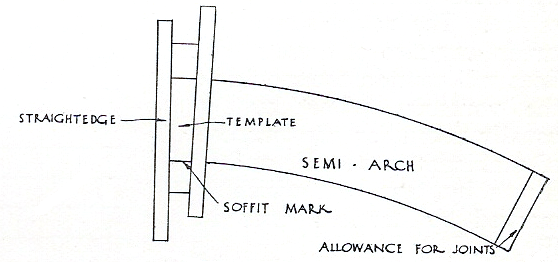

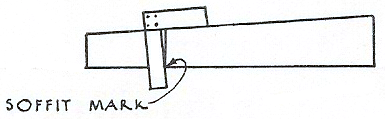

Traversing the mould

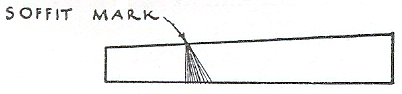

Fig. 60a - Volume 14, page 652

Place the template with one edge against this straight-edge, and position it until its other edge is the thickness of one joint away from the other side of the key, as drawn on the setting-out boardFig. 60a - Volume 14, page 652

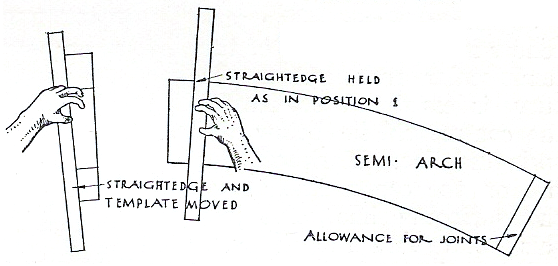

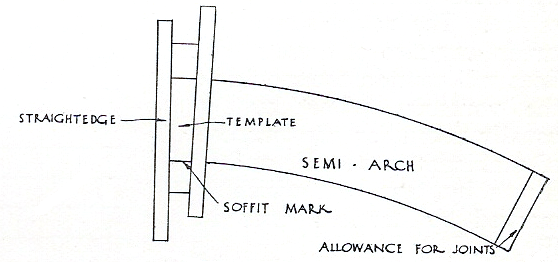

Now mark on the edge of the template a point coincident with the soffit line. Place the second straight-edge against this edge of the template, hold it firmly in position, and with a sliding motion draw both the template and the first straight-edge away; now place the first straight-edge against the edge of the one you are holding, and hold that firmly in position

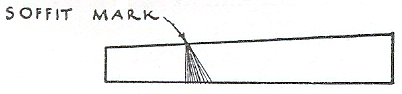

Traversing the mould

Fig. 60b - Volume 14, page 652

This is now in the same position as the edge of the template last occupied. The template is now applied in its second position with the pencil-point again on the line of soffit. This process is repeated, and if the template is accurate it should finish with its edge parallel to the line drawn, and which makes the allowance for the jointsFig. 60b - Volume 14, page 652

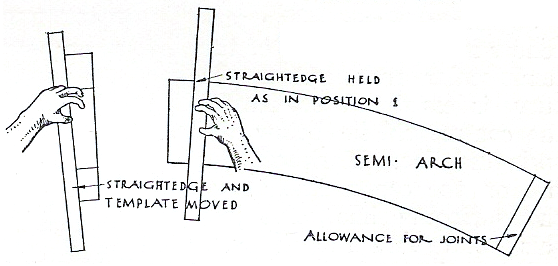

Should it fall directly on this line, there will be no further need to repeat

Traversing the mould

Fig. 60c - Volume 14, page 652

Should it finish short of the line, start again from the key and put the soffit mark a little higher. This slightly increases the width of the voussoirs. Then traverse the arch again. This process will have to be repeated until the edge of the template finishes in contact with the line.Fig. 60c - Volume 14, page 652

If, in the first traverse, the template finishes beyond the line, then the soffit point will have to be moved down,

this slightly diminishes the width of the voussoirs

The Soffit Bevel

Square a line across the template from the pencil-point which marks the soffit line, reverse the square, place its stock against the other edge of the template, and draw a line from the same point.

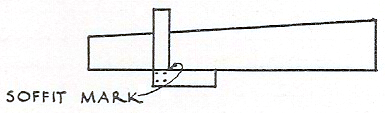

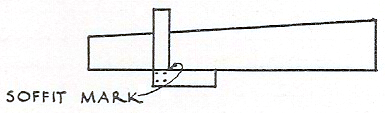

Marking the soffit bevel on template

Fig. 61a - Volume 14, page 653

You will then have two lines across the face of the template, making an angle which has its vertex on the soffit-point. Bisect this angle, and the bisector gives the required bevelFig. 61a - Volume 14, page 653

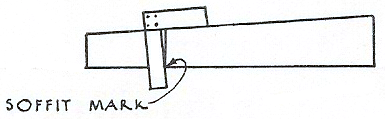

Marking the soffit bevel on template

Fig. 61b - Volume 14, page 653

This will also be the bevel of the transverse joints of the arch, and of the extradosFig. 61b - Volume 14, page 653

In a camber arch, the soffit bevel for every course is different, and should be transferred from the setting-out drawing to the template when the traverse has been completed

Obtaining the soffit bevels for Camber arches

Fig. 62 - Volume 14, page 653

It must not be overlooked that in this arch there are right-hand and left-hand voussoirs for each side of the archFig. 62 - Volume 14, page 653

Cutting the bricks

In axed work, a rough bench is required for scribing the bricks, and a cutting block for the axing. The actual method depends on the type of brick and the particular kind of arch

If the soffit bevel is very slight, it is best to cut, or rub, this bevel on the brick first. But if the bevel is acute, or if the bricks are glazed, the craftman will be compelled to leave the soffit untouched, and cut both sides of the brick to the wedge-shaped template

A good method in axed work is to tack a thin strip of wood across the template to the soffit line, and apply the mould with this strip abutting the end of the brick

Scribe the edges of the voussoir with a tin saw, which is usually a piece of tin plate let into the edge of a wood block and used like a mason’s grub saw

The saw is worked backwards and forwards, against the edge of the template, until a fine cut about ¼" deep is made in the face of the brick

The edges outside the cut are removed with the boaster, and the rough irregular surfaces trimmed with the scutch to form true beds

Each course of the arch is stacked as it is cut, until the whole arch has been completed. If the cutting has been accurately done, the work will stack close and the courses will not rock, or wobble, although they are unset

This is an excellent criterion of good workmanship

Work that is cut well will stack well

No comments:

Post a Comment